SUPERMOLECULAR TREATMENT WITHOUT CHEMISTRY

Water vapour treatment

The main goal of supermolecular steam treatment is to obtain economic, energetic and ecological benefits for clients who use steam, regardless of the type of industry, whether it is energy, textile, food or other industries.

Water vapour problems

The main side effects of water vapour include damage to the piping system and internal parts of technical equipment due to cavitation and the formation of incrustations. Problems most often occur during the energy production in power plants, due to the peripheral speed of the turbine blades, when cavitation occurs. The cause is the high oxygen content in the water. The formation is also affected by the value of surface tension and the viscosity of the water from which the water vapour is produced.

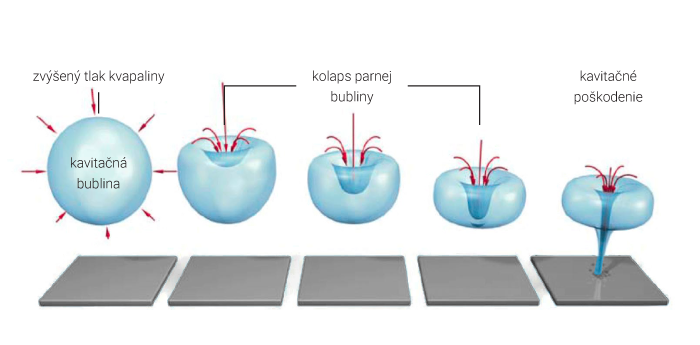

Cavitation

Cavitation increases the surface roughness by tearing out the material. This is how so-called cavitation wear is formed, causing the reduction of the equipment efficiency. It occurs especially in technical devices moving rapidly in a liquid, e.g. on turbine blades, high-pressure pumps, pipe bends, etc.

Water vapour treatment with Treasure ©

The Treasure © device can accelerate the degassing time of water vapour by molecular treatment of water (from which water vapour is produced) and produce so-called dry water vapour, which limits unwanted cavitation. This is due to an increase in viscosity and a decrease in surface tension of the water. Another advantage of molecular treatment is the faster heating of the water from which water vapour is produced. This generates an energy saving of at least 15 % for heating. At the same time, financial savings are generated by avoiding damage to stressed parts of the equipment, thus reducing repair costs and extending the life and efficiency of the equipment. In conclusion, we would like to point out that we can design the Treasure © device so it can change the physical properties of water for steam production according to the specific client requirements.

1.

increase viscosity (fluidity) of water

2.

decrease in surface tension of water

3.

acceleration of water vapour degassing (oxygen separation)

Use in industry

Pharmaceutical industry

Disinfection of instruments in water vapour sterilizers used for medical purposes.

Energy

industry

eating plants producing heat/domestic hot water based on a water vapour system. Water vapour production for turbine drive in power plants.

Textile

industry

Drycleaners, laundries, carpet and textile production, textile colouring, textile ironing, water heating in washing machines and others.

Food

industry

Various processes requiring water vapour to maintain product quality (steaming, cleaning, cooking, pasteurization, distillation, stewing, baking, canning) or surface sterilization.

Other industries

using water vapour